Nikel coated inten bubuk sintétik

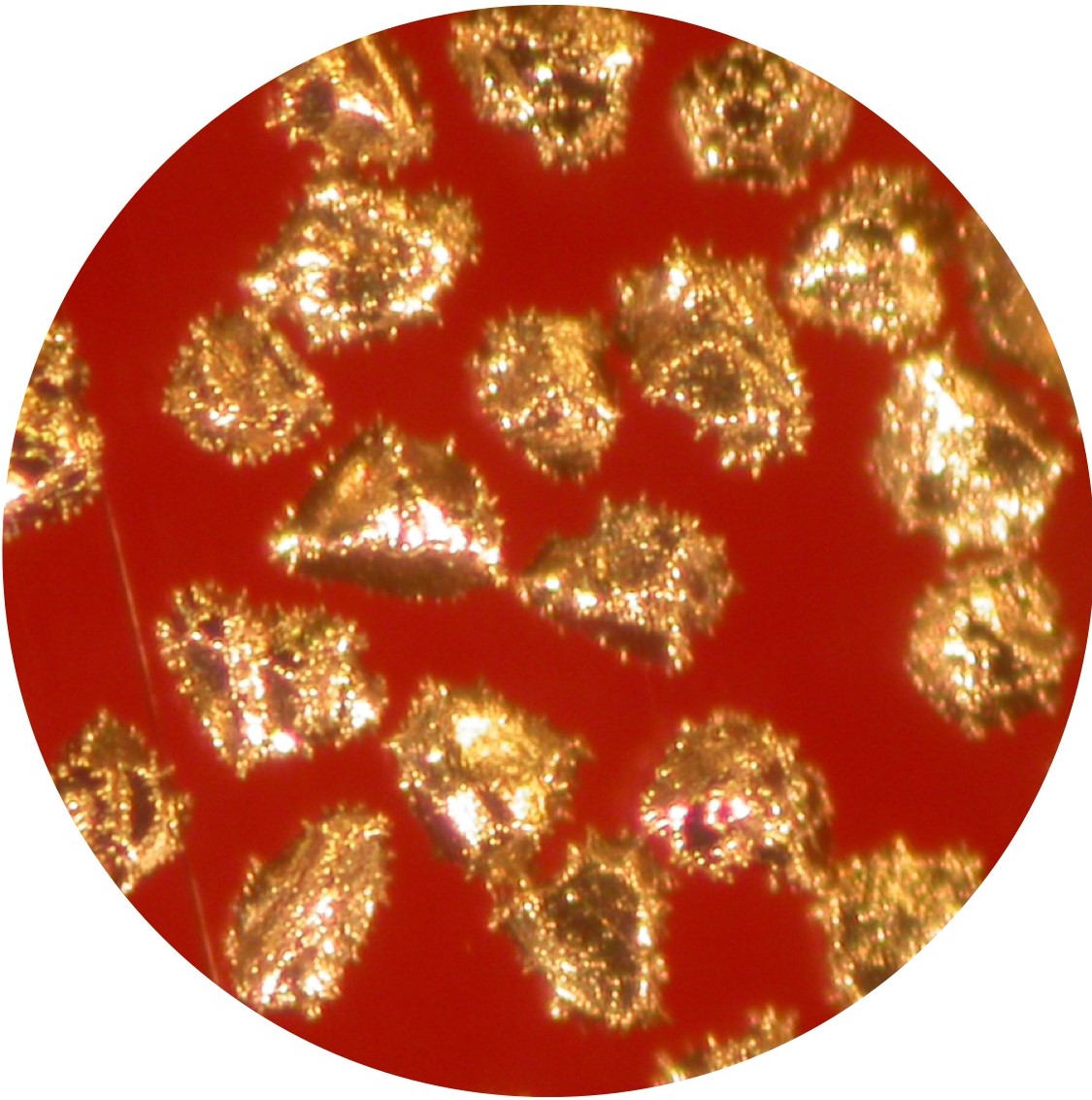

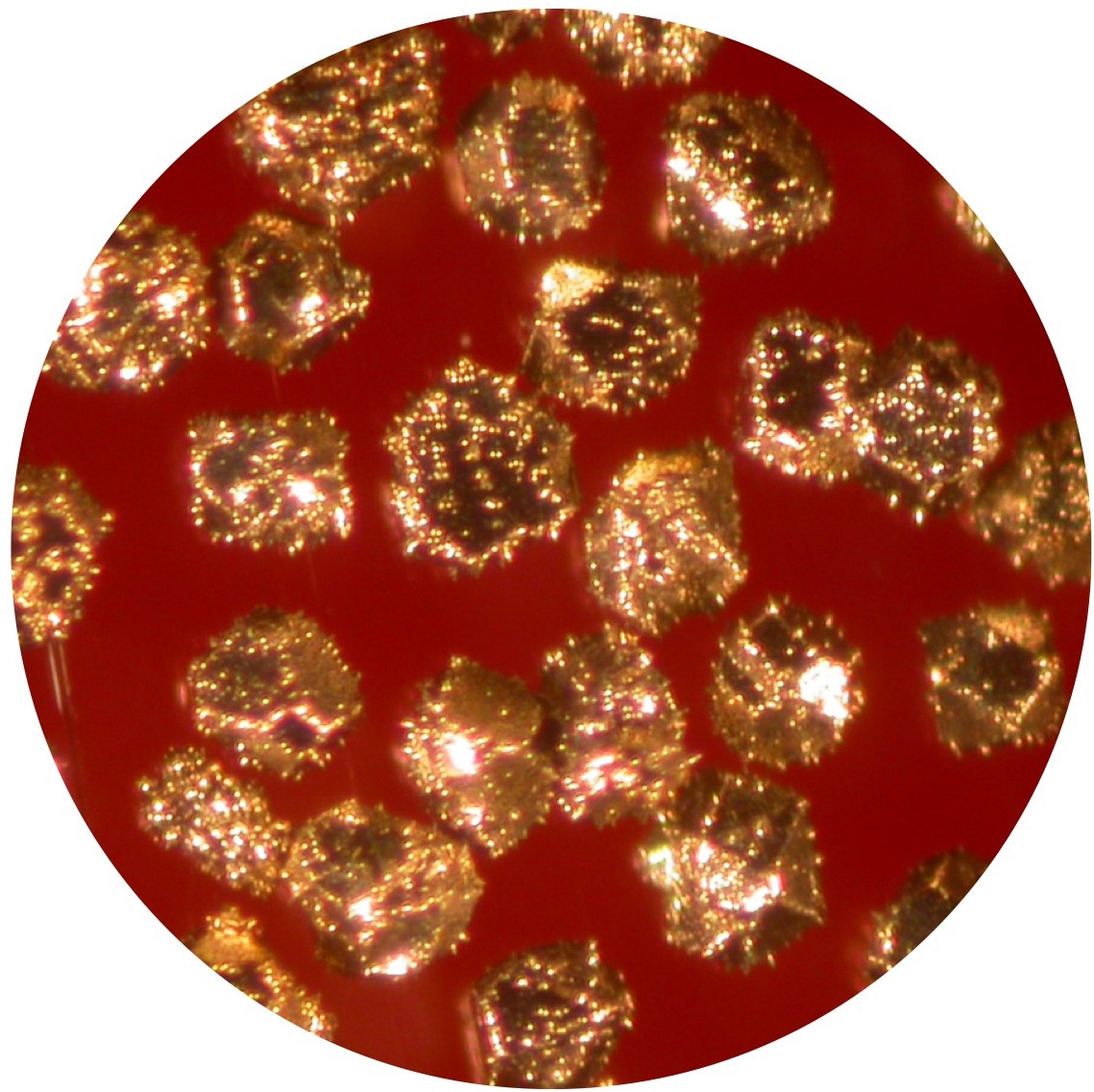

Coated Inten nikel coatedBubuk Inten sintétik

1. Coated Inten Bubuka

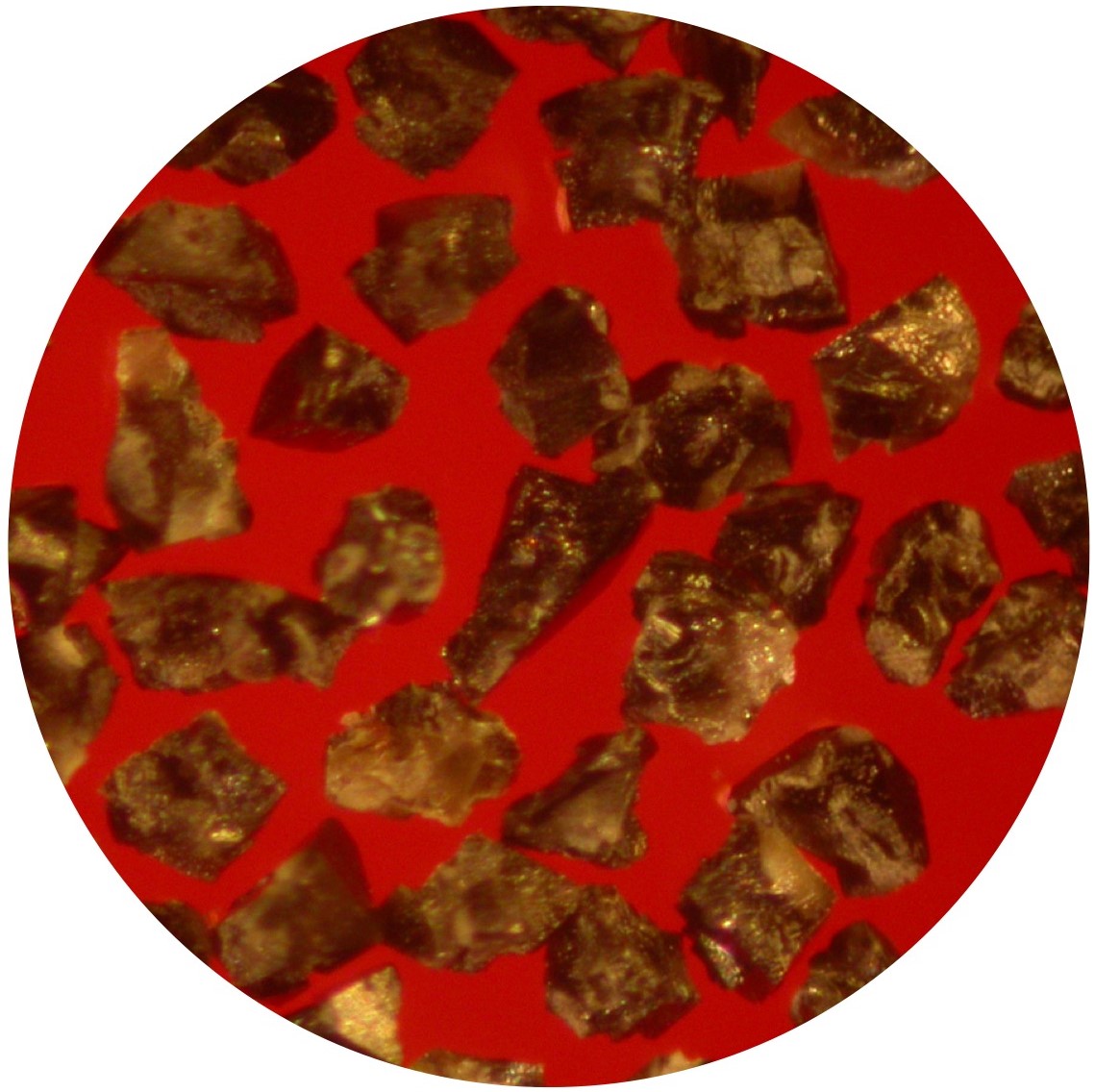

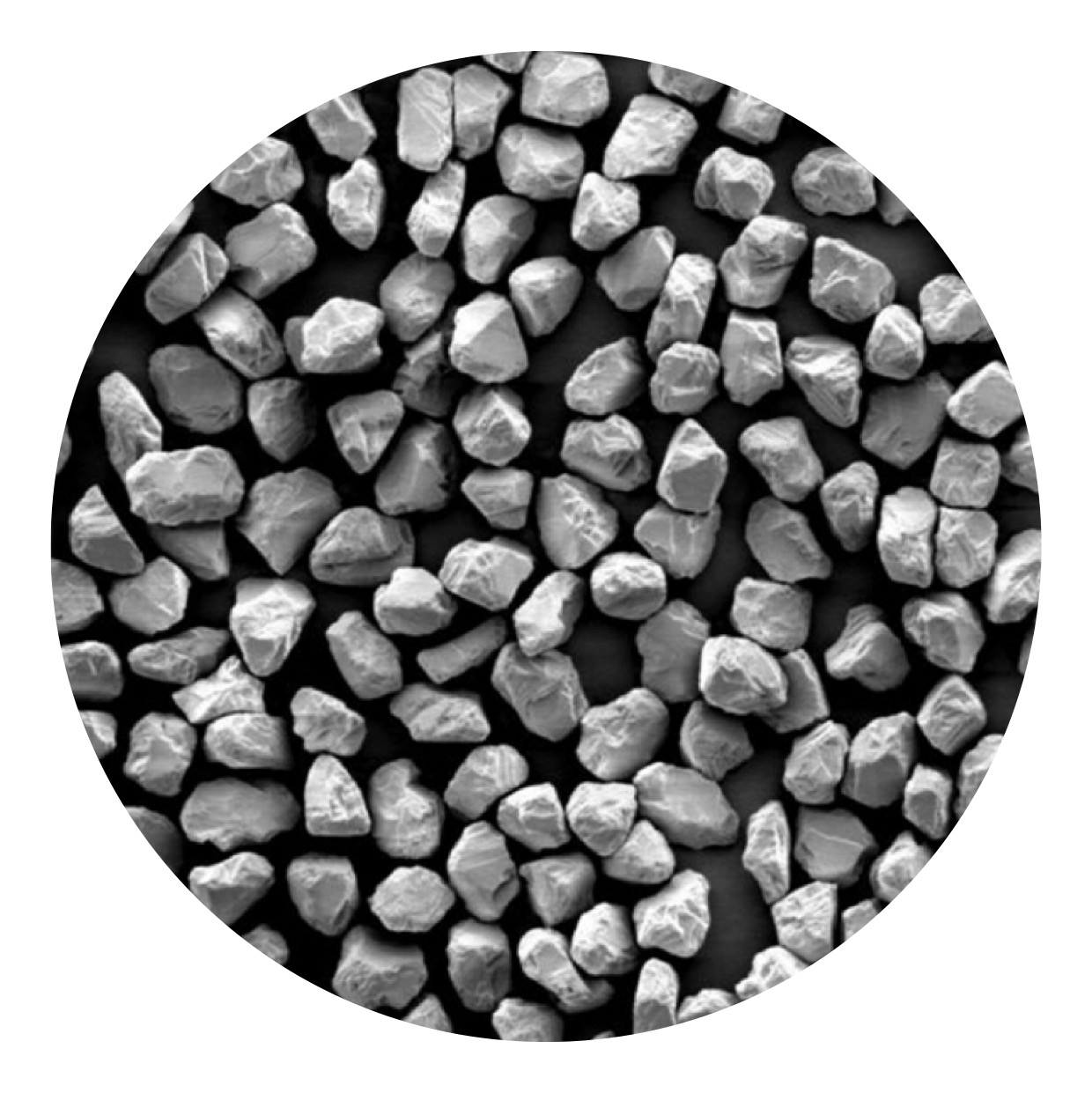

Inten coated, bisa kuat adhesion Metalurgi antara Ti jeung matrix, ngaronjatkeun kantétan mékanis tina inten ka matrix beungkeut.Plating tiasa ngasingkeun inten tina oksigén pikeun nyegah inten dioksidasi kusabab suhu anu luhur, anu tiasa ningkatkeun ciri ingetan mékanis inten, sareng ningkatkeun dissipation panas sareng kahirupan polishing.

2. Fitur tina Ni coated Inten

- Beungeut kasar jeung spiny, ngaronjatkeun ingetan antara inten jeung beungkeut, ulah inten peeling kaluar mimiti, sahingga, manjangkeun umur jasa tina parabot inten.

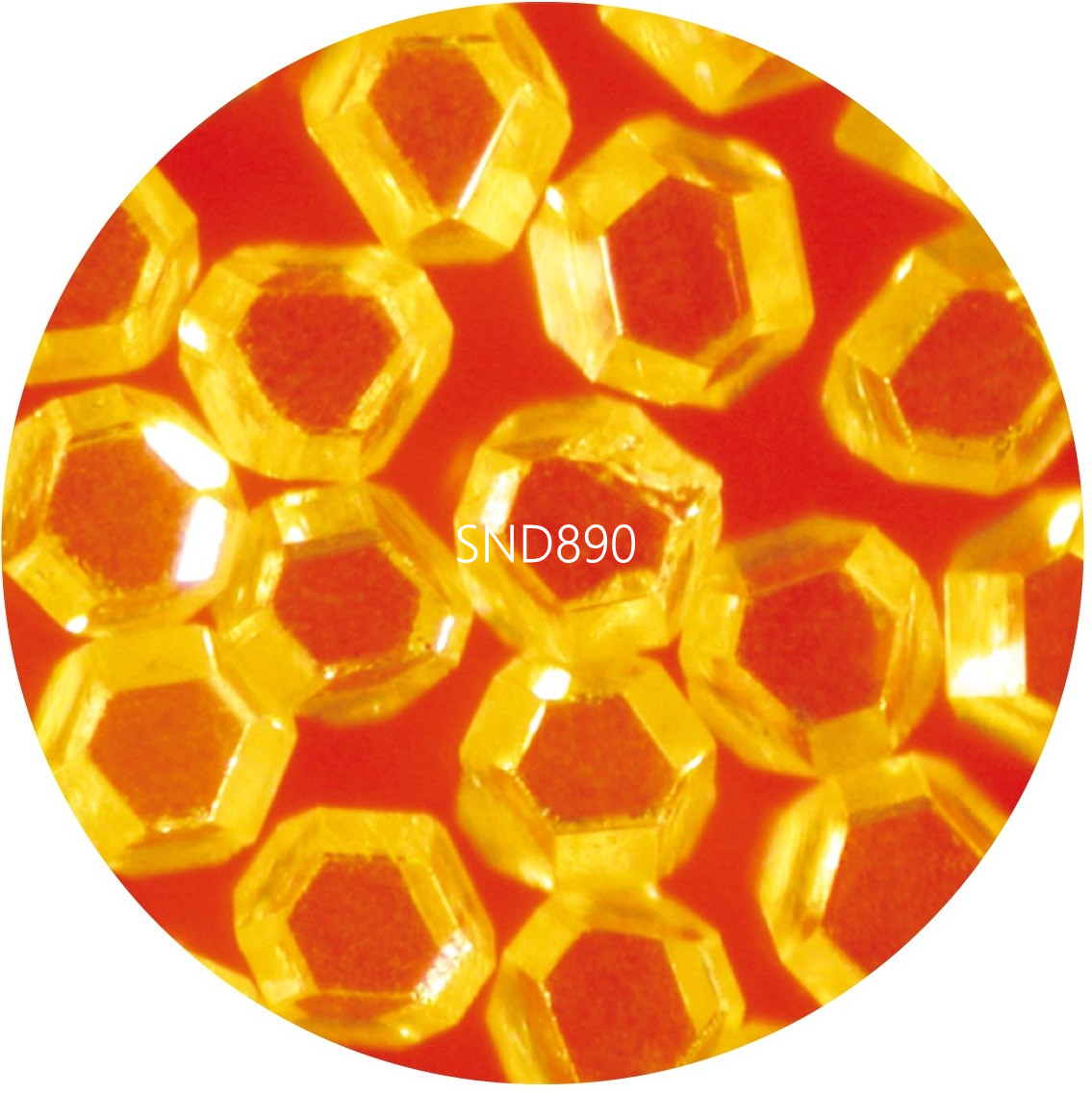

- Electroplating jeung kimia plating;Ngaronjatkeun beurat 30% sareng kéngingkeun beurat 56%.

- Nyarankeun pikeun nyieun parabot inten beungkeut résin, Contona, résin beungkeut inten grinding kabayang.

3. Ni coated Inten Ukuran

Inten grit ragaji kami, inten ukuran bolong, inten naksir, inten mikron kalolobaan kelas sareng ukuran tiasa dilapis.

| 30/50 | 50/80 | 80/100 | 100/120 | 120/140 | 140/170 | 170/200 | 200/230 | 230/270 | 270/325 | 325/400 | |

| SND-G05 | X | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND-G10 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND-G15 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 80/100 | 100/120 | 120/140 | 140/170 | 170/200 | 200/230 | 230/270 | 270/325 | 325/400 | |

| SND-G20 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND-G30 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND-G40 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND-G60 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 20/25 | 25/30 | 30/35 | 35/40 | 40/45 | 45/50 | 50/60 | 60/70 | 70/80 | |

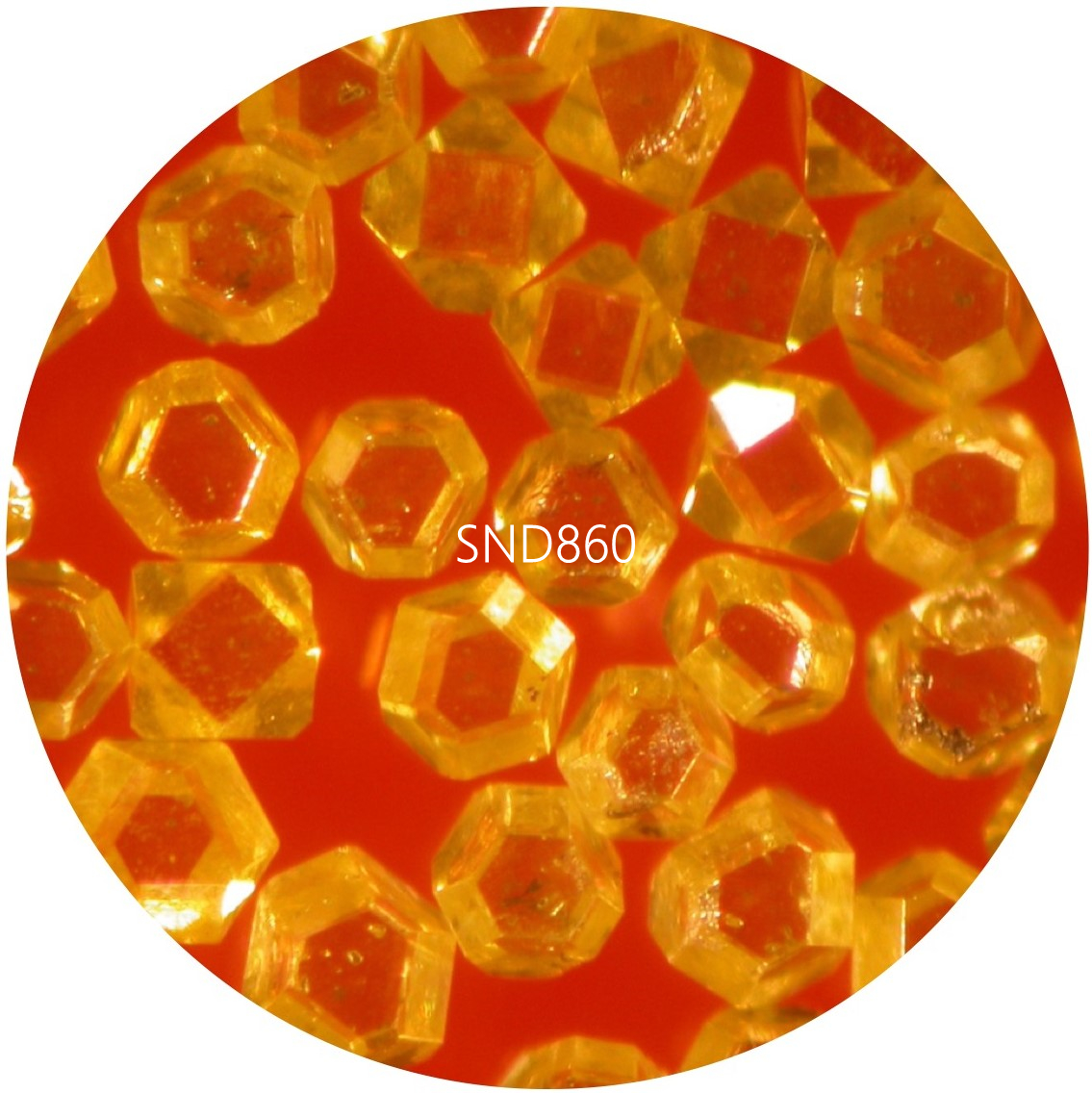

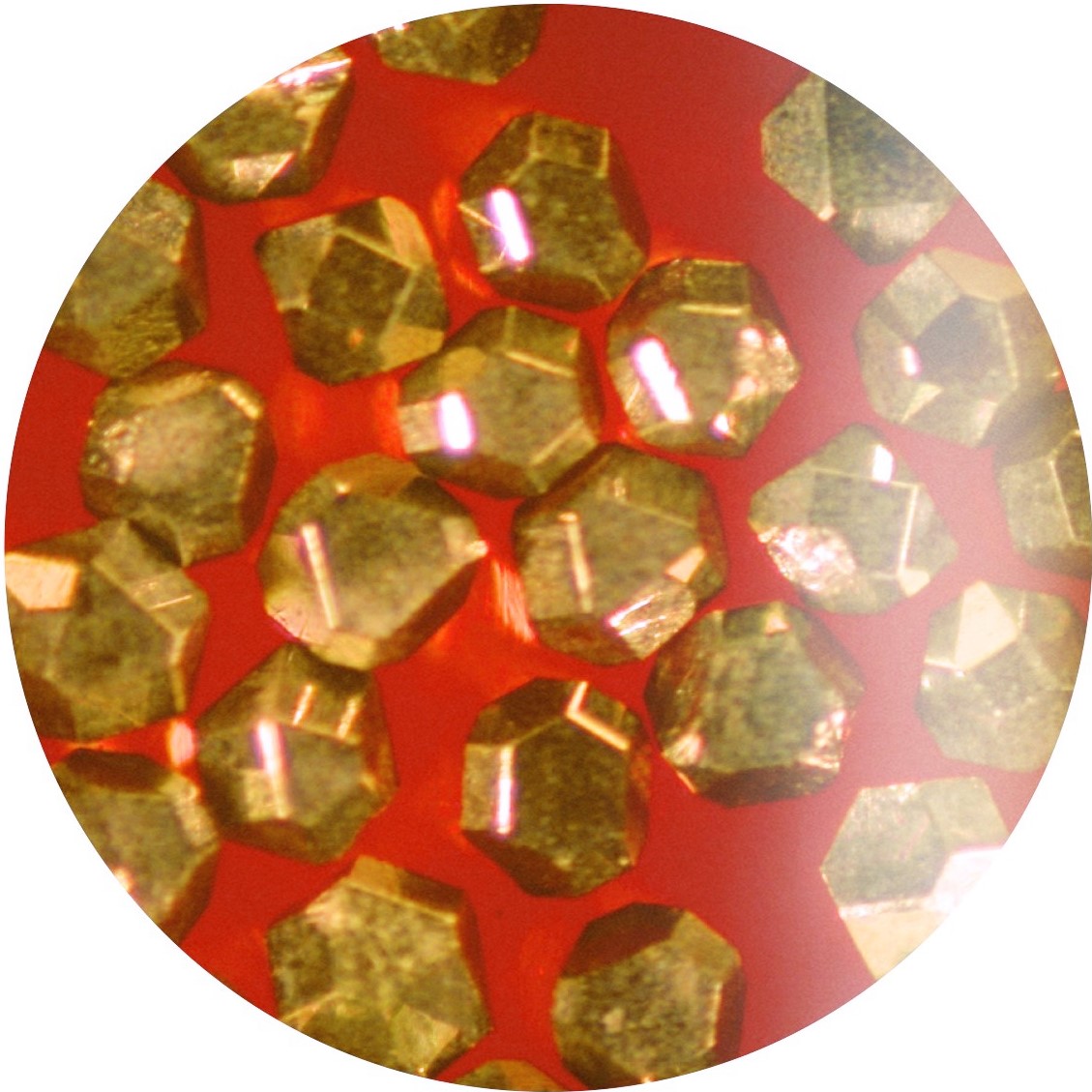

| SND820 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND830 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND840 | x | x | √ | √ | √ | √ | √ | √ | √ |

| SND860 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND870 | x | x | √ | √ | √ | √ | √ | √ | √ |

| SND880 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND890 | √ | √ | √ | √ | √ | √ | x | x | x |

4. Téhnologi palapis Metal séjén

| Tipe Beungkeut | Disarankeun palapis |

| Beungkeut logam | Titanium, Tungsten, Molybdenum, Chromium, Zirconium |

| Beungkeut résin | Nikel, Tambaga, Aluminium, Beusi-Nikel Alloy, Cu-Tin Alloy |

| Beungkeut Vitrified | Tungsten Carbide, Titanium Carbide, Karbon-Titanium Nitride, Aluminium Titanium Nitride. |